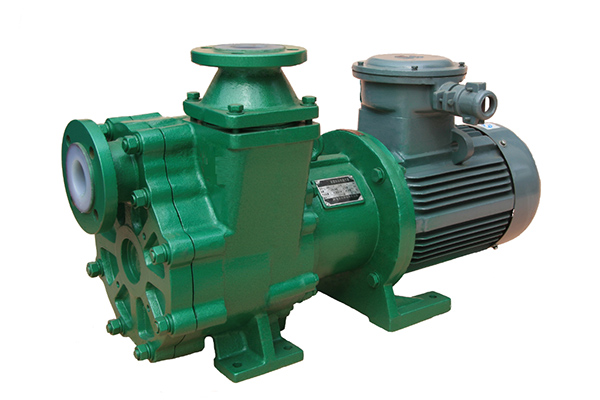

ZMD Self-priming ponp

● ZMD Self-priming Pump

● Ponp chimik plastik

● Self-priming Pump

Imèl: [imèl pwoteje]

Main Done teknik

● Koule: jiska 400 m3/h, max 1761 GPM

● Tèt: 80 m; 410 pye

● Tanperati: - 20 °C a +150 °C; -68 °F pou +302 °F

Aplikasyon

● Petrochemicals,

● Non-ferrous metal metallurgy,

● Pesticide,

● Acid and caustics,

● Pulp production,

● Acid pickling process,

● Rare- earth separation,

● Galvanization,

● Electronics etc

Ponpe likid

● Acids & lyes

● Dechè dlo

● Chlorine water

● Electrolyte

● Dlo klò ak tretman dlo ize

● Endistri petwòl

● Endistri chimik

● Adding acid process.

konpetitif Advantage

Ponp Lojman an

● Virgin Fluoroplastic

- Konsidere pi fasil ak plis serye kontwòl kalite

- Pa gen rediksyon nan rezistans a pénétration

- Pi famasetik ak medya chimik amann: pa gen okenn kontaminasyon

● With ductile cast iron casing absorbs all the hydraulic and pipework-forces. According to DIN/ISO5199/Europump 1979 standard. Comparing to plastic pumps, no expansion joints are required. Flange with service-minded through holes to DIN, ANSI, BS; JIS. For flushing system and monitoring device as required, the draining nozzle will be offered.

● Spacer sleeve made of Carbon-fiber-reinforced plastic [CFRP]

-Sistèm nan metal-gratis pa pwovoke nenpòt ki kouran eddy e konsa evite jenerasyon chalè nesesè. Efikasite ak fyab operasyonèl benefisye de sa. Menm pousantaj koule ki ba oswa medya tou pre pwen bouyi yo ka Se poutèt sa transmèt san entwodiksyon chalè.

● Close Impeller

-Closed impeller with flow-optimized vane channels: for high efficiency and low NPSH values. The metal core is protected by a thick-walled seamless plastic lining, the large metal core and increase the mechanical strength considerably even at elevated temperature and high flow rates. Secured screw connection to the shaft to against loosening if the pump is started up in the wrong direction of rotation or in the case of back-flowing media.

● Bearing

-The main characteristics of SIC are extreme hardness, high-temperature, anti-corrosion, small expansion coefficient, long service life.

EN

EN  AR

AR FR

FR RU

RU ID

ID VI

VI